Table of Contents

Project THOUGHT Frictionless Hybrid Joint

Able to operate in Frictionless, Mechanical/Legacy, or Hybrid mode; this joint was designed for use in a next-generation Mecha as both a limb joint and potentially for thrust vectoring nozzles. It is intended to be able to move with speed and precision in its frictionless mode, but switch in the blink of an eye to a mechanical mode when more strength is required.

History

For two years, Kage Yaichiro had been attempting to remove the bottlenecks from the limb manipulation speed and flexibility systems existing in Power Armors of the time, and had explored multiple concepts. With the appearance of larger Mecha and Fighters on the battlefield, however, the scope of the project shifted to making a larger and more powerful design which still met the above criteria. Project THOUGHT, the name of the effort to produce such a machine, finally made a large leap forward with the design of a frictionless system which allowed maximum precision and speed, but could still switch to a stronger mechanical mode.

Basic Description

The type of joint used is more often than not a ball and socket which allows for maximum play and movement, though the same techniques can easily be applied to simpler lever or axle-type joints. In the broadest sense, this joint is typically driven not by the transfer of mechanical motion, but a less direct stimulation which does not create friction between the interacting parts as a mechanical joint would. Early prototypes used customized Scalable Graviton Beam Projectors, but it was decided to move to more powerful electromagnets for the sake of strength and better general operation. This system allows higher speed and flexibility than a mechanical system would allow, though it can switch back and forth to a mechanical mode at any moment desired – without interruption of operation. The main downside to this design is the difficulty in calibrating it for maximum precision and speed, as well as adjusting to its rather wide range of movement. It is also difficult to apply armor to protect the joints, though some measure of protection is afforded by integrating a cover into the joint itself.

Operation and Repair

NOTE: Not all ball and socket joints using this technology actually use the ball as the fulcrum. This can cause confusion when conducting repairs or analyzing movement.

Due to the joint's nature as a hybrid design, it is more complex than a standard joint to produce – requiring specially designed parts in both the actual joint and the parts the joint is set into. It can take time to assemble and calibrate, but is incredibly responsive once completed. This joint was originally designed to be able to react as quickly as possible to a NH-22C Yamataian's or NH-29's telepathic commands while in use, and it shows. Control is relatively easy with the right operating system, as the intent of the pilot can be detected and allow the joint to move or even toggle between modes automatically. It should also be noted that the frictionless nature of the parts make them far easier to remove and swap out, allowing units to be repaired more quickly if spare parts facilities are available. It also notably reduces wear.

Joint

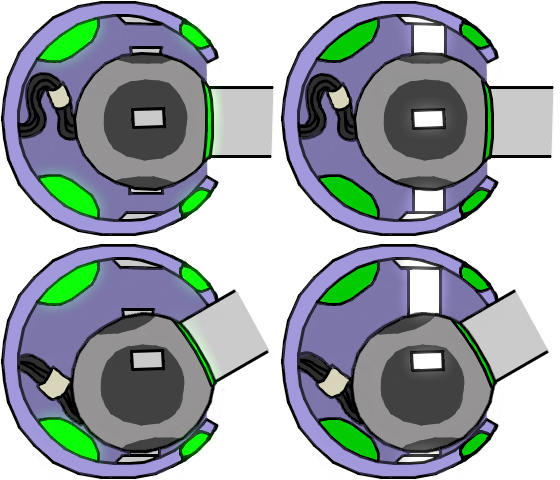

The basic prototype joint can be seen below, with its cover removed for the sake of simplicity:

On the left side, the joint is operating in Frictionless Mode. Multiple electromagnets (glowing green) control the movement of the joint with precision and speed, though not with as much strength as a solid Yamataium joint would normally have. It is, however, more than sufficient for operating in high gravity, holding a weapon, sustaining recoil from said weapon, etc. The multiple magnets can exactly control the movement, speed, and direction of the joint for quick execution and precision. Note, however, that the anchors slightly sticking out of the joint are always oriented the same way regardless of how the joint is oriented.

On the right, however, the magnets have been deactivated and a group of retractable anchors has locked into connectors inside the joint's socket. This takes place very quickly to allow combat to continue, and is intended to be used when strength is needed over speed by the device utilizing the machine. This is known as Mechanical, or Legacy Mode. The speed is still formidable though, and it is possible to use both modes at once for yet more strength while retaining precision.

When Mechanical Mode is supplemented by the use of the Frictionless systems, it's known as Hybrid Mode – which increases strength to its maximum.

In combat uses where electromagnets are utilized, the inside of the socket is typically lined with an impregnated Yarvex Foam to both fully insulate the interior from excess voltage or stray electromagnetic interference and prevent shrapnel from entering the joint. It also prevents the electromagnetic forces from interacting with anything other than the joint, preventing the energies from escaping and allowing the suit to be as easily detectable. Should it be damaged, it is designed to be able to regenerate a Faraday Cage made of Yamataium or for an engineer to add another cage made of more conventional metals until a more permanent fix can be made with spare or fabricated parts.

Rotation

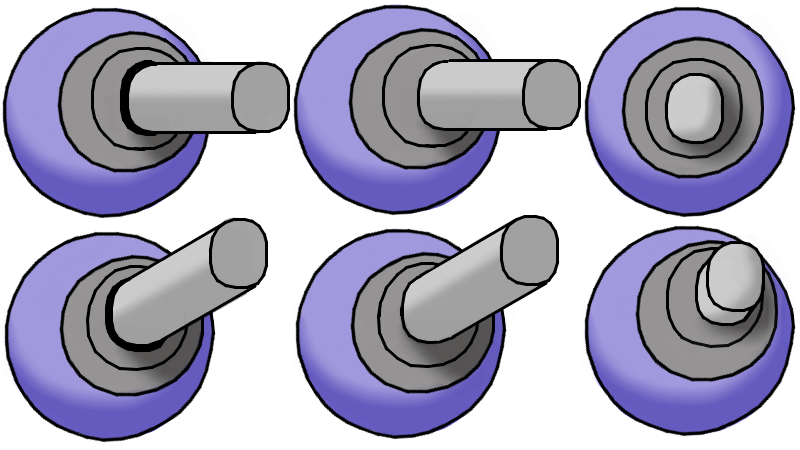

When in frictionless mode, the ball can rotate within the socket freely as well, though it will do its best to stay aligned for prompt switching to mechanical mode. In Mechanical mode, a system allows the shaft to rotate within the ball, completely independent of the socket. When switching modes, the mechanical rotation of the shaft actually takes over and briefly compensates for when the Frictionless system has to align the ball anchors to the socket for anchoring in mechanical mode. This is done very swiftly, and is intended to be imperceptible.

It is a bit hard to describe, so in summary, there are two points of rotational articulation. One for frictionless mode (the ball free-rotating in the socket), one for mechanical mode (the shaft rotating inside the ball), the latter of which compensates for the former's alignment when switching modes.

Cover

One issue with the design of the joint is that its range of motion makes it hard to apply supplemental armor to. With this in mind, a special cover has been added which is made of several overlapping rings, rounded gently like the end of a sphere so as to better operate with the system and better contain the ball within the socket if needed. The covers are usually lined with the same impregnated Yarvex Foam to protect from shrapnel and provide the same electromagnetic insulation as the socket. Like the socket, this can be replaced with a Faraday Cage made of Yamataium or another metal if the needed parts are not available.

The overlapping rings are able to slide over each other as well as the surface of the socket (or can be bolted to the socket if so desired) with merely the shaft of the joint exposed. In Frictionless Mode a very small low-power force field is used by emitters on the joint itself to both keep the cover slightly (a fraction of a millimeter) away from physical contact with the joint, as well as prevent electromagnetic forces and matter/vacuum from entering or exiting the joint. This is to keep friction off the joint in frictionless mode. While the cover is not frictionless, it is designed to be able to keep up with the speed and precision of the frictionless mode due to its simplicity. The force-field is so minute in size and power consumption that it is designed not to appear on enemy sensors, even when this design is applied to the entire unit's joints. Of course, supplemental fields and devices can further minimize the risk of detection, as well as using Mechanical/Legacy mode or both modes at once to remove the need for the force field's operation altogether.

When the joint shifts to Mechanical/Legacy mode, the cover closes completely over the joint and makes a air/water/vacuum-tight seal to completely enclose the joint. This also happens when both modes are engaged. This also results in the deactivation of the force field.

The function of the joint is not merely to protect the joint's inner workings from the environment or sensors, but it is also designed to protect the joint against attack. Most combat grade covers can be several centimeters thick at minimum assuming the joint to be mecha-scale, usually constructed of Yamataium to protect against normal wear as well. The exposed part of the joint, the shaft pictured above, is quite thickly armored Yamataium typically, with power and data flowing through yarvex-lined conductors in its core. While supplemental armor is always desired if possible, these measures afford more than adequate protection to the joints without restricting their range of motion.

Intended Uses

This joint is designed to appear in joints for Mecha designed as part of Project THOUGHT's Beta generation of designs, though it is also considered an option for thrust vectoring both Mecha and Starfighter engines. Other uses may exist, but this is the main reason for the system's development. The unit is designed to move as swiftly and precisely as possible; to take full advantage of an IES', a Yamataian's, or a Nekovalkryja's improved response time.

Downsides

While beneficial, the system has several downsides. It is impractical for a being with a more conventional human mind (Napleslian, Geshrin) to use this system as it does not provide a sufficient performance gain to justify it – mechanical joints are sufficient to translate their movement effectively and at the appropriate response time. Also, while the expense is not so much a consideration for a faction that can synthesize its own materials, the length of detail means that it takes time to assemble and calibrate the unit.

Due to these issues, a second solely mechanical version of the joint was produced, notably simplified compared to its high-performance sibling. It was dubbed the Project THOUGHT Simplified Joint.